Efficient in-house electricity generation and decarbonisation

cement industry

High exhaust gas temperatures from rotary kilns provide constant high-temperature waste heat for power generation.

Steel and metal processing

Foundries and rolling mills continuously generate usable process heat – perfect for the integration of modular energy systems.

Chemical industry

Exothermic reactions and steam generation provide usable heat across a wide range of temperatures.

glass and ceramics industry

Combustion and melting processes generate uniform waste heat, ideal for recovery and conversion into electricity.

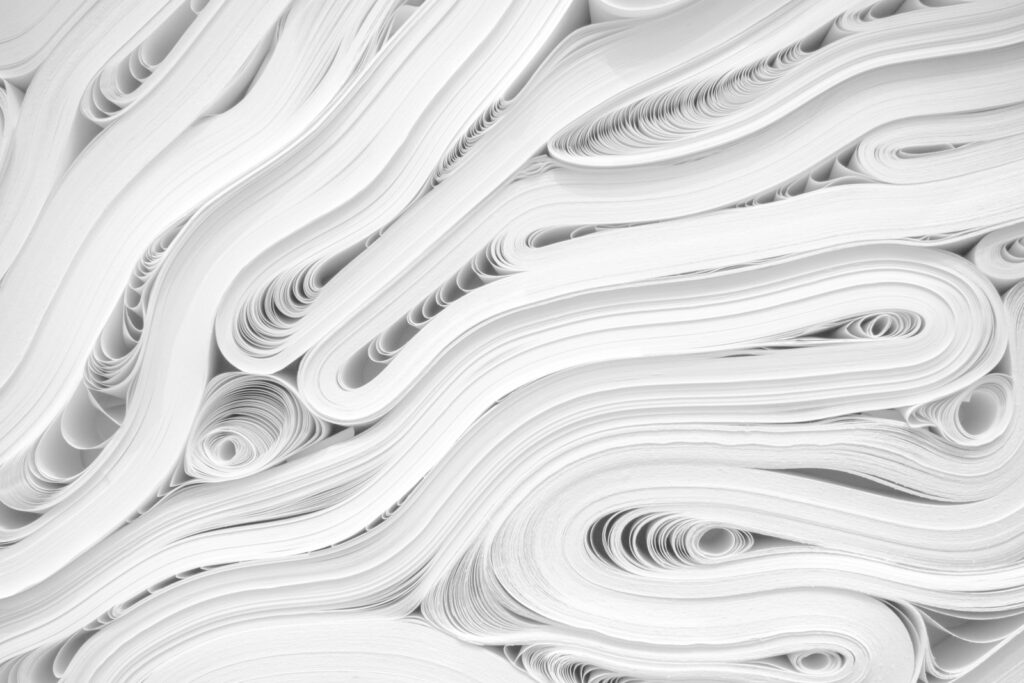

Paper and pulp industry

Large quantities of waste heat from drying processes enable economical utilisation by ENERGY TOWERS – even at moderate temperatures.

cement industry

High exhaust gas temperatures from rotary kilns provide constant high-temperature waste heat for power generation.

Steel and metal processing

Foundries and rolling mills continuously generate usable process heat – perfect for the integration of modular energy systems.

chemical industry

Exothermic reactions and steam generation provide usable heat across a wide range of temperatures.

Glass and ceramics industry

Combustion and melting processes generate uniform waste heat, ideal for recovery and conversion into electricity.

Paper and pulp industry

Large quantities of waste heat from drying processes enable economical utilisation by ENERGY TOWERS – even at moderate temperatures.

Utilise energy that is already available.

Decarbonizing

ENERGY TOWERS convert industrial waste heat into CO₂-free electricity. This means that every degree becomes a real opportunity for climate protection.

Recover electricity

Process heat is already available. ENERGY TOWERS make it possible to use this heat efficiently—without additional fuel.

Energy-efficient and economical

The intelligent use of waste heat not only reduces CO₂ emissions, but also electricity costs, especially in energy-intensive industries such as cement, steel, and chemicals.

Easy to integrate

The modular design of ENERGY TOWERS allows for seamless integration into existing industrial processes without the need for major modifications.

Retrofittable & scalable

Whether for individual lines or entire sites: ENERGY TOWERS can be flexibly scaled and integrated into existing systems as a retrofit solution.

Future-proof production

With ENERGY TOWERS, companies lay the foundation for net-zero strategies, ESG goals and eligibility for subsidies. The starting signal for visible impact on the environment and balance sheet.

On to

waste heat utilisation

Eligible for funding through energy efficiency programmes.

The recovery of industrial waste heat is supported by numerous programmes, for example in the context of decarbonisation, efficiency or own electricity generation. We can help you choose the right subsidy and submit your application.

Seamless integration into your processes.

From existing plants to new buildings: ENERGY TOWERS can be connected to your existing waste heat sources in a modular fashion. Together, we will clarify feasibility, approvals and interfaces.

Activate waste heat. Now

Opportunity seen & seized

These partners already trust in a green future with the ENERGY TOWERS.